ZEUS-86

Twin Drive System Large-Scale High-Precision Machining Centers

This design concept reexamines the origin of our design and returns to core principles, without taking any shortcuts in the specifications. It is a bold undertaking, carrying on the Roku-Roku spirit of making high-precision, high-speed machining centers. Ideas freely conceived, without any old stereotypes, have resulted in new performance and beauty to meet modern expectations. All-Around Design: Zeus-86

| Axle Movement (XYZ): | 800 / 600 / 400 mm |

| Spindle End Format: | 1/10 short taper (two-sided restraint) |

| Spindle Speed: | 200 – 25,000 rpm |

| Tool Shank Format: | HSK-E50 |

| ATC Tool Storage Capacity: | 30 tools (OP: 60 tools) |

| Machine Weight: | 8,000kg |

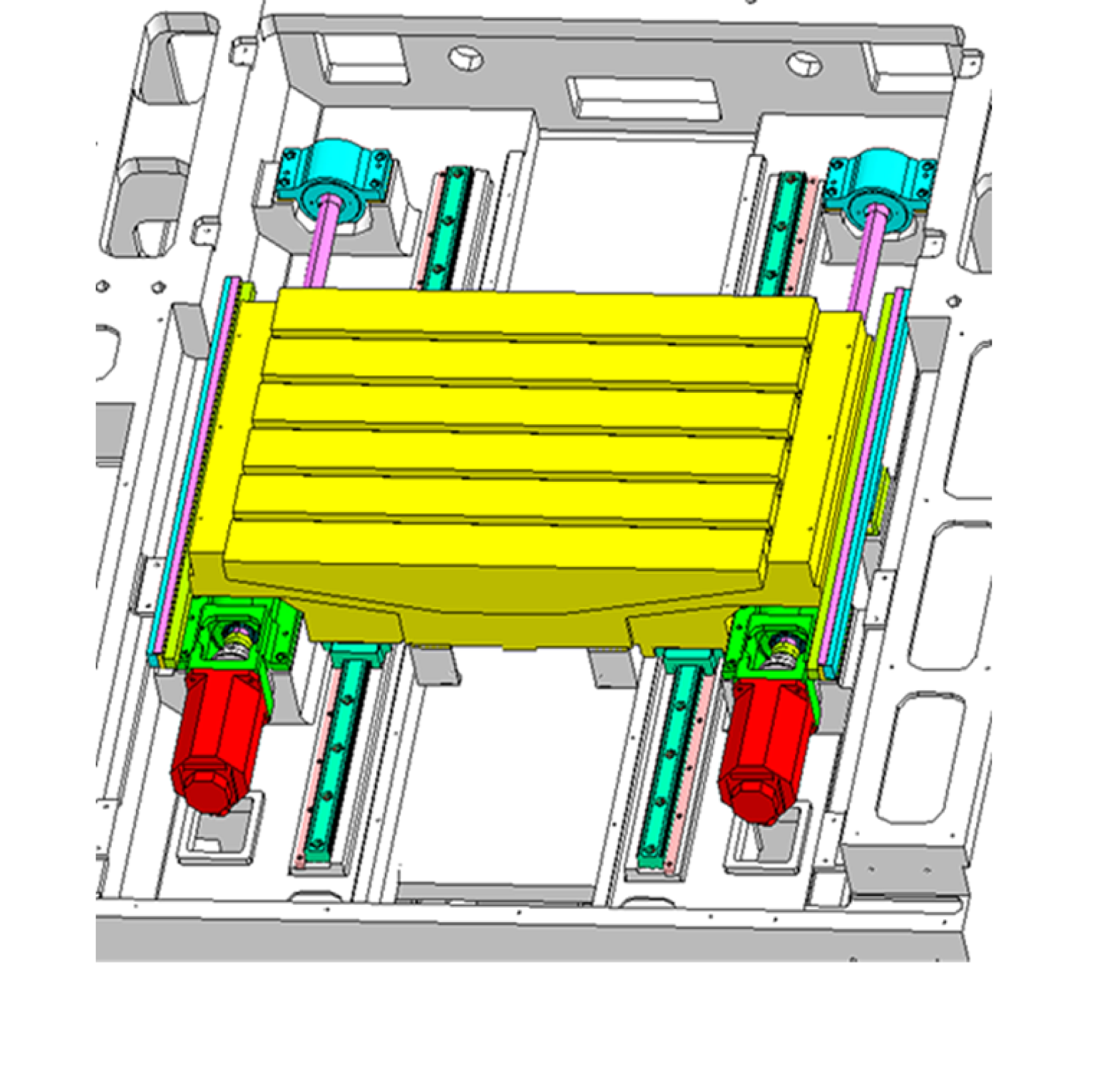

- Uses a Y-axis twin ball screw drive system. Realizes high-level tracking for minute pitch feed commands, and reliable thrust for large and heavy workpieces.

- Ensures axial feed straightness precision (on the “vertical plane” and “horizontal plane”) at the same level as a Roku-Roku High-Precision Micro Machining Center.

- Reduces position displacement in the Y-axis direction of the spindle. Following increased proximity of the spindle center to the Z-axis guide, the X-axis structure slides along the top surface of the crossrail. Position displacement in the Y-axis direction is minimized by keeping the saddle center of gravity inside the column.

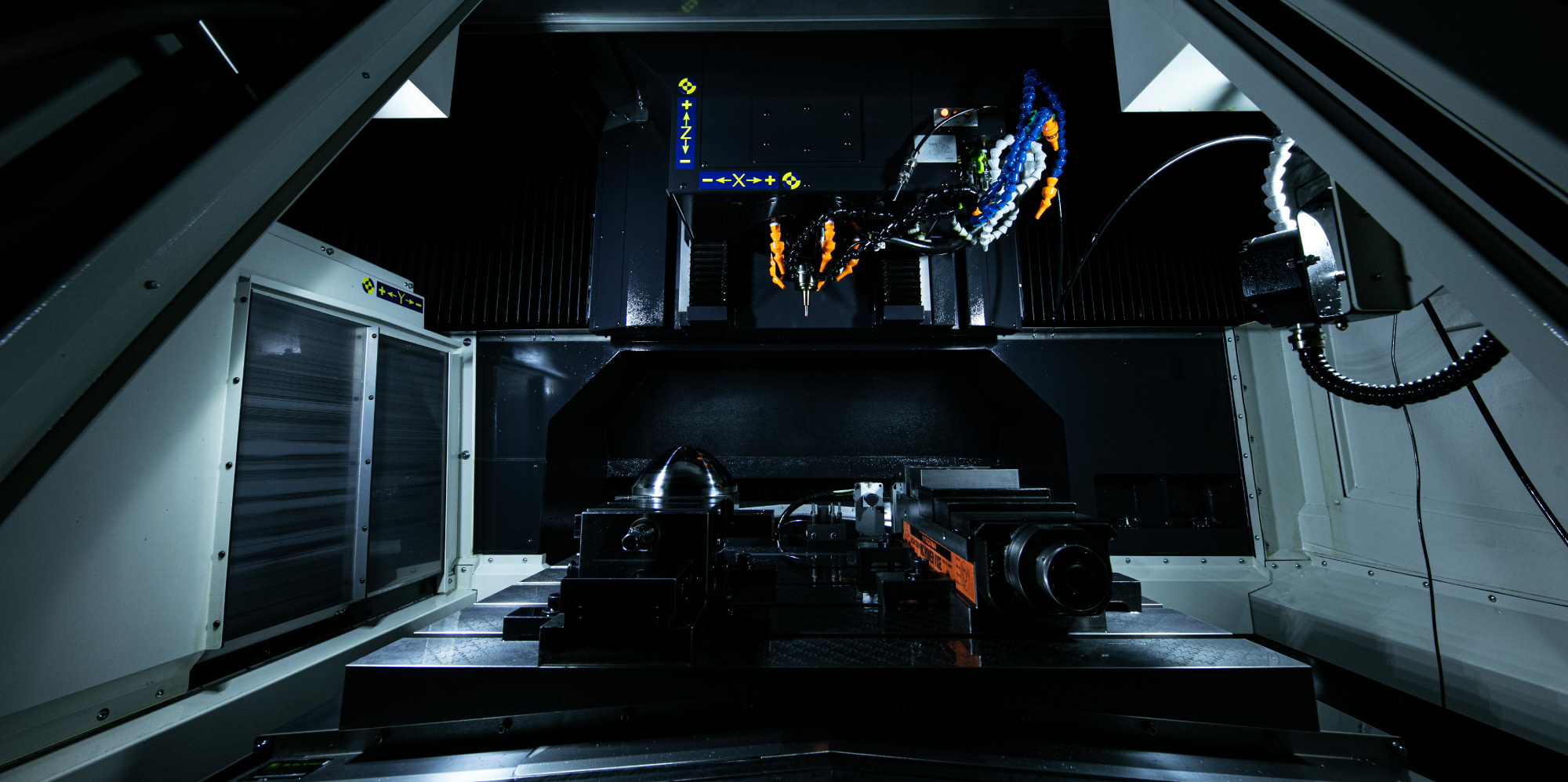

- Comes equipped with a ceramic ball bearing high-performance spindle, and succeeds in suppressing vibrations, shaking, and heating in a wide rotation range. The spindle characteristics enable free and flexible adaptation to any machining scenario.

Positioning capability that follows completely

- Linear scale feedback comes equipped standard on all axes. Offers the highest level resolution 0.002 μm (2 nm). It reliably secures high precision positioning capability, against a rough environment, aging, and heat sources due to continuous operation.

- By equipping a Z-axis balance cylinder, we ensure an ideal weight balance of the spindle head unit and housing. Equalizing the load on the Z-axis drive motor and feed screw ensures incredibly smooth vertical movement, and guaranteed reliable follow-up performance relieves stress from the tip of the tool. In combination with high-quality machining, this greatly contributes to extending the useful lifespan of tools.

Other features

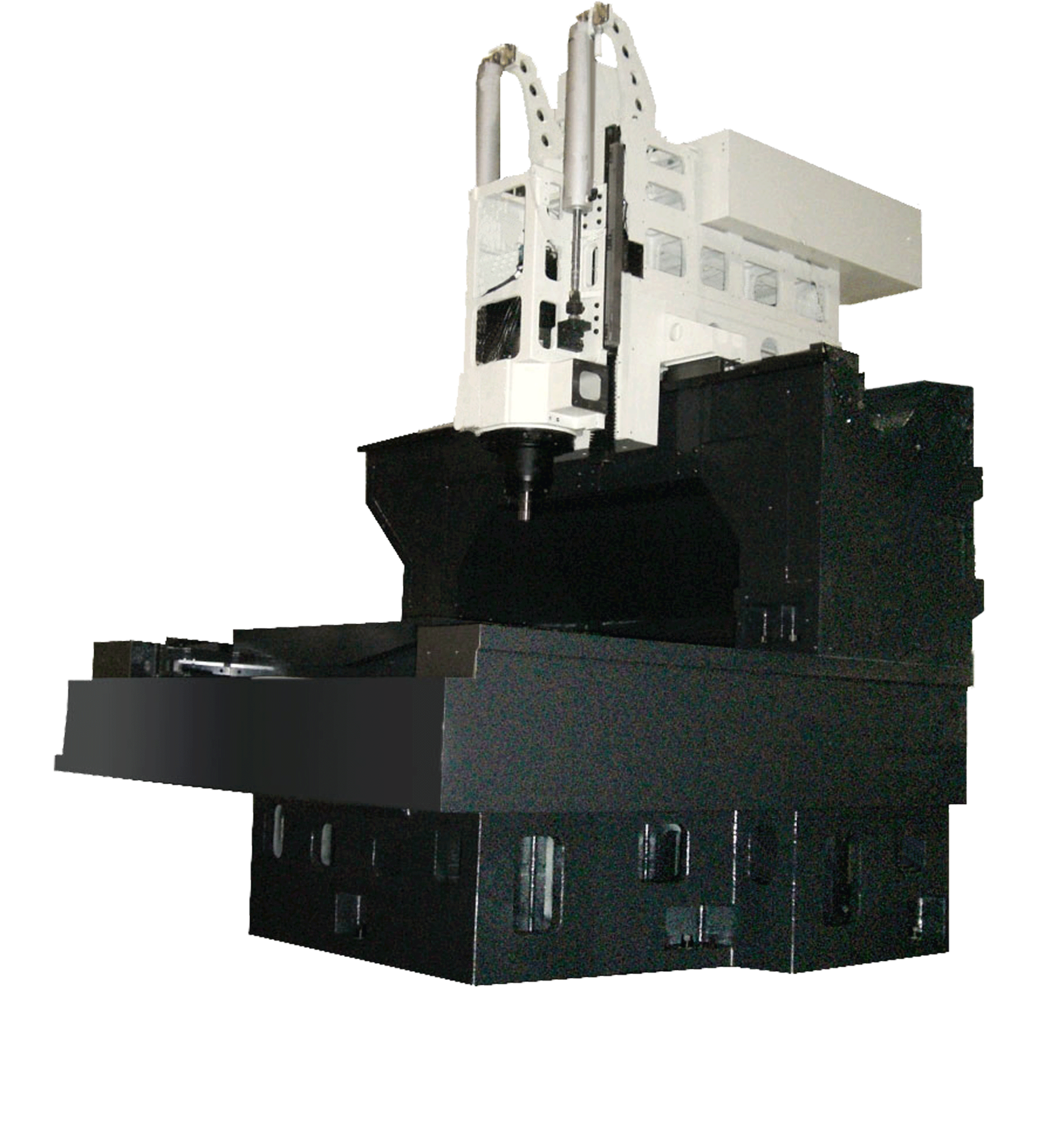

- Uses a thermally symmetrical frame. The symmetrical structure minimizes position displacement effect caused by temperature changes in the installation environment, and ensures strong rigidity and vibration dampening. Position maintenance capacity rare among large models guarantees absolute regularity and stability.

- Uses a highly rigid gate-shaped structure, with a column and crossrail cast as one integrated part. Vertical ribs inside the crossrail adapt to strain deformation caused by the weight of objects moving along the X-axis and the machining load. The special rib structure is also arranged with varying thickness according to the position, in order to suppress vibration. Heavier weight and thicker special rib design ensure the highest level of rigidity and reduced vibration in the class, as well as reliably showing high precision and high speed positioning capacity.