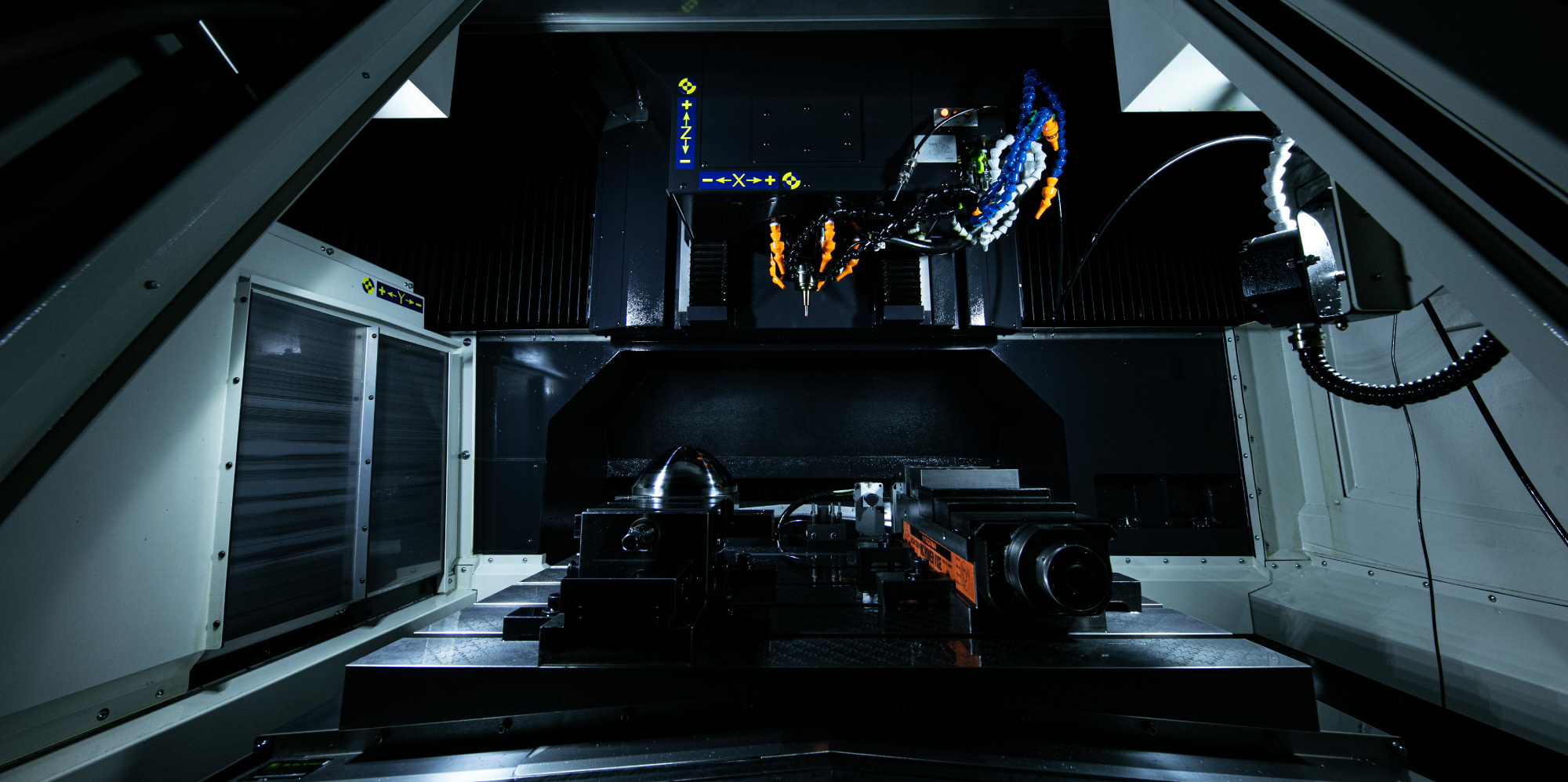

CEGA-SSS

Super Precision Micro Machining Center

We have developed a highly versatile micro machining center, capable of doing everything from rough cutting to high-precision, high-quality machining in a single unit, thereby consolidating multiple processes. This micro machining center can be connected to “AI Machine Dr.”, which comes with a unique function that visualizes the status of the machine and makes it possible to manage the status, in order to maintain the best possible machining environment. … 5th Stage [CEGA-SSS]

| Axle Movement (XYZ): | 510 / 410 / 310 mm |

| Spindle Speed: | 200 – 30,000 rpm (SSS-300 200 – 40,000 (SSS-400) |

| Spindle End Format: | 1/10 short taper (two-sided restraint) |

| Tool Shank Format: | HSK-E40 |

| ATC Tool Storage Capacity: | 20 tools (OP: 40 / 60 tools) |

| Machine Weight: | 5,200kg |

New Operation System: Equipping MA-OS1

- Uses a FANUC iHMI 10.4 inch touch panel display (sub monitor is optional)

- We have developed an intuitive, easily understood screen using GUI with Roku-Roku proprietary functions

- We present to you a new operation system, which stimulates the senses of machining artists.

Evolved usability

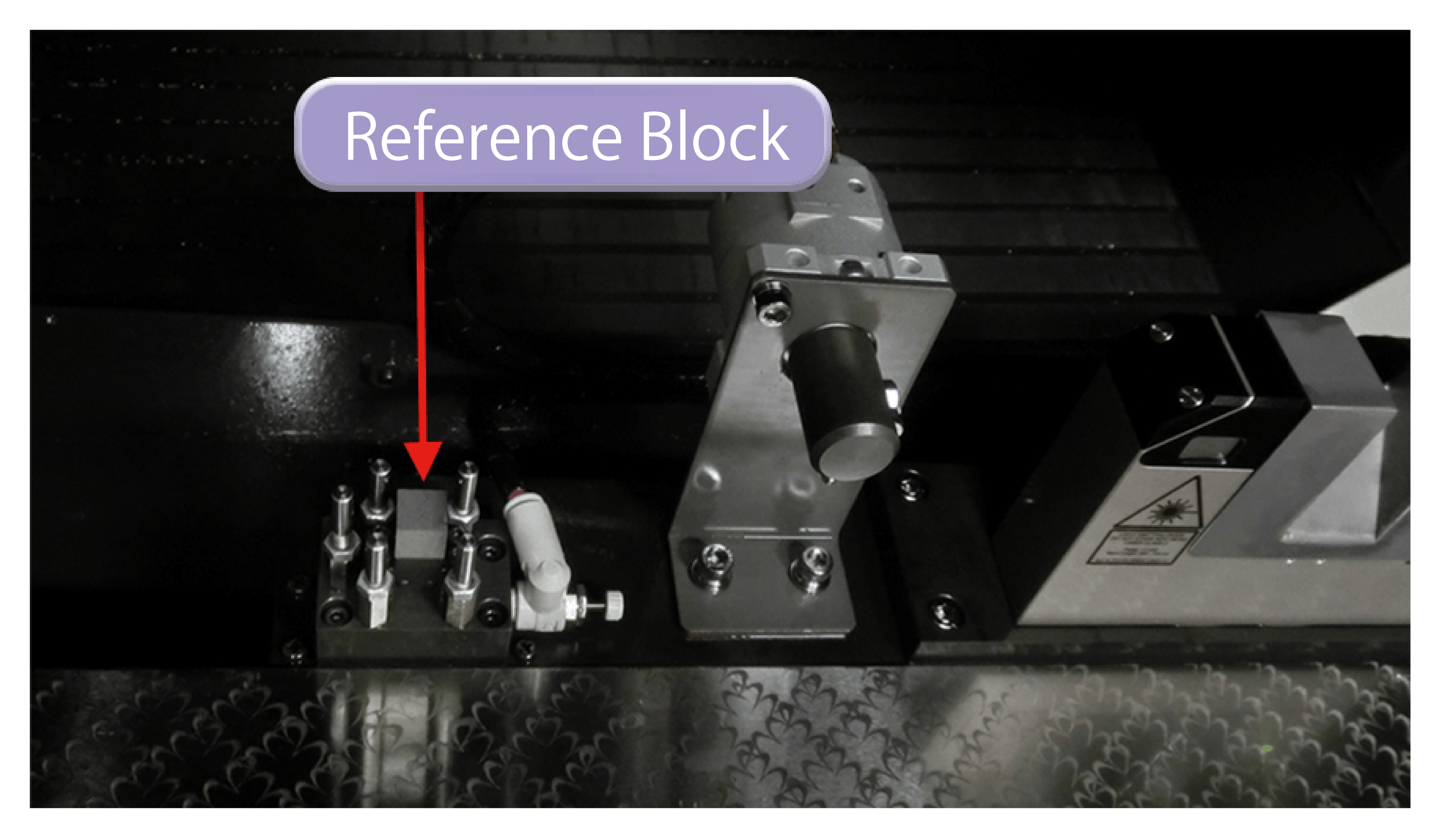

Comes equipped with an automatic calibration function

Both auto-centering devices and non-contact tool measurement devices

can be easily calibrated with simple controls

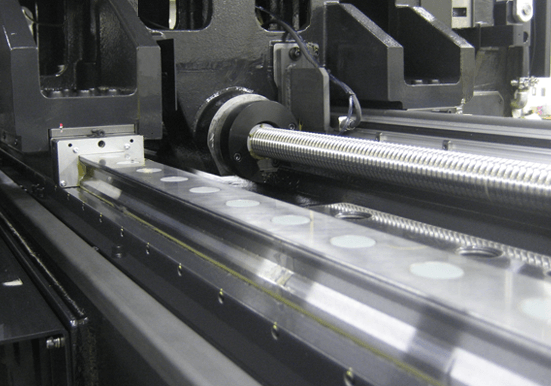

Ultra Precision Tracking & Positioning Capability

- Uses a “cylindrical roller precision guide” for all three X/Y/Z axes

- X-axis feed screw cooling

- A feed screw for driving with minimum lead, with the largest diameter in the class

- Pursuing total balance of X/Y/Z axes

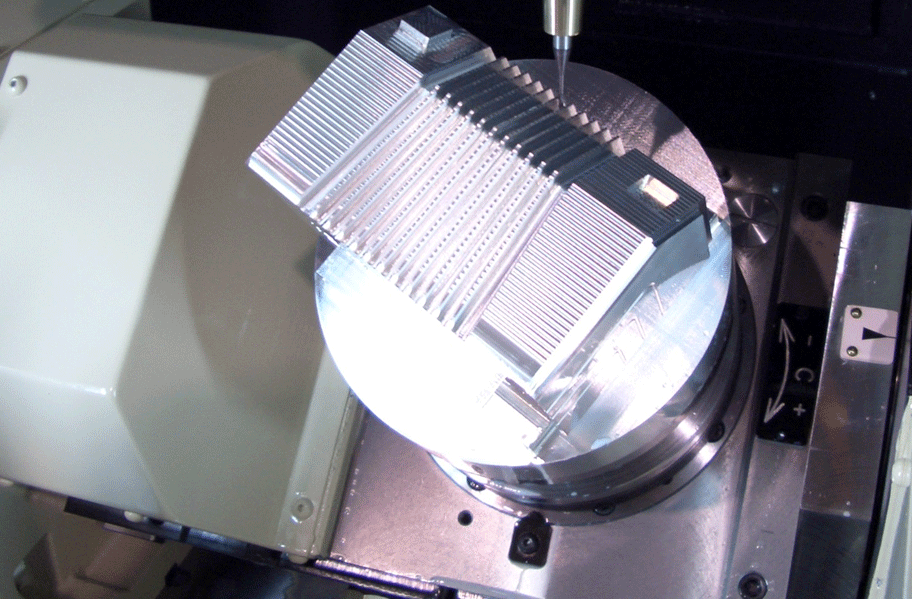

Ultra High-Precision Added Shaft Specifications Machine: CEGA-SSS / 5AXP

This machine has specially engineered simultaneous five-axis control specifications, which promise ultra high precision machining, thanks to the CEGA-SSS’s XYZ three-axis positioning capabilities and extremely small thermal displacement.

Supports multiple applications, including ultra high-precision dies, medical, optical, and electronic device part processing

- Exclusive design that comes standard with scale feedback on both the tilt axis and rotation axis

- Strong support rigidity is ensured with the pneumatic clamp system when machining with the shaft tilted

- Can be equipped with chucks from various holder companies (Erowa / System 3R: Special specifications)

- Higher efficiency, higher precision, process integration

- Using the tilt axis and rotation axis makes it possible to specify the machining point from any position or direction, avoiding collision of the tool and workpiece, while simultaneously keeping protrusion of the tool short. Advantages of this include the ability to ensure proper conditions for maintaining tool rigidity and reducing runout, as well as improving machining precision, machined surface quality, and tool lifespan.

Automatic Work Changer System : Machining Cell

- Change Precision: ± 1μm (actual measurement value)

- Changer positioning elements are compatible with various holder companies (Erowa / System 3R)

- A rich software setup that flexibly compatible with schedule management functions and emergency interrupts that support long-time operation

- Unique chip treatment enabling completely unmanned continuous operation

Dedicated nozzle for cleaning on jigs, and forced chip discharge mechanism

Specifications which have a proven record of verifying in detail and responding to the possibility of chip contamination

| AHC [Specifications 1] | APC [Specifications 1] | APC [Specifications 2] | |

| Work Stocks: | 24 / 40 / 60 units | 33 surfaces | 45 surfaces |

| Max Dimensions of Carried Object [W x D (mm)]: | 70 x 70 | 200×190 mm | 100 x 120 |

| Max Dimensions of Carried Object [With nothing adjacent (mm)]: | 70 x 130 | ー | ー |

| Max Height of Carried Object (mm): | 130 (including holder height) | 150 (including holder height) | 85 (including holder height) |

| Max Weight of Carried Object (kg): | 5 kg (including holder) | 20 kg (including holder) | 10 (including holder) |